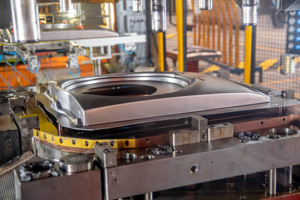

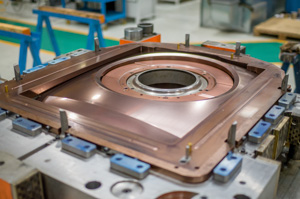

Dynamic development, gaining new markets and increment of the production enable to modernize the park of mechanic and hydraulic presses as well as to develop modern tooling.

The own tool-room with research and development background and the appropriate machine park is able to meet customer’s requirements.

Screen printing & pad printing

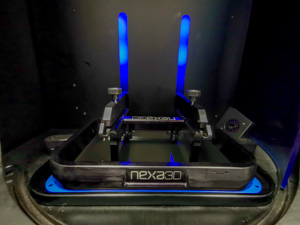

One of the pillars of Italmetal is continuous development. This manifests itself in precise observation of market dynamics, brave investments and constant introduction of new products. One of them is a pilot screen printing project, thanks to which the company can meet greater customer needs.

The screen printing technique, thanks to its universality, allows apply paint to many materials, e.g. wood, fabrics, plastics and metals as well.

The external panels we produce which for the household appliances are marked with prints containing information such as the serial number, logo, list of wide range programs of washing machine and dishwasher or common known icons as well. Now we can make those prints in-house, provide customers with fully finished parts and be self-sufficient.

How is the print created?

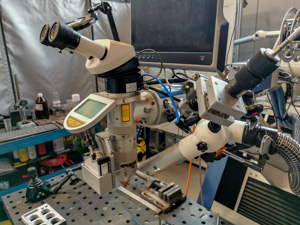

A room dedicated for screen printing meets specific requirements in terms of humidity and temperature. The conditions are much more sterile than in the production floor, there are no sawdust and filings. Thanks to this, we can ensure the highest quality of printing. Such conditions are just perfect for the brand new machines purchased in 2022: two machines for screen printing, one for pad printing, and devices for controlling the quality of prints by imitating water vapor, a situation typical of dishwashers. The department's equipment is complemented by a special oven in which the paint is hardened on the material.